Série Serie 421XXXX

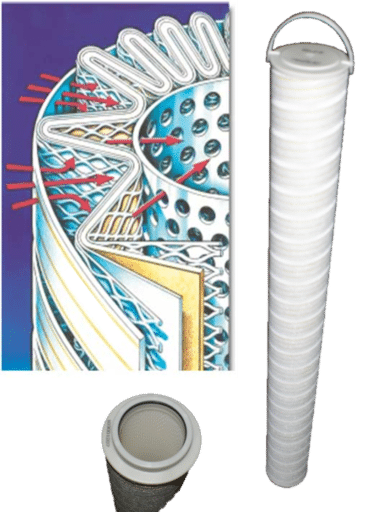

Filter element

Fichiers PFD

Series 421XXXX

Features

- Glass fibre elements are covered by a protective sheath, this is a thin, perforated plastic sheet that completely encases the pleats of the filter from the outside as well as making the element more stable. This minimizes bending of the pleats and possible damage to the filter element, even under severe conditions of cold start or pressure overload, providing reliable performance.

- The plastic structure of the ends incorporate flow channels facilitating oil circulation, thus minimizing the effects of pressure drop and maintenance costs by increasing element fatigue cycles. A bypass valve is integrated in the filter element and allows the oil to bypass the contaminated filter element if a defined pressure differential is exceeded.

- The choice of the right filter material is dependent on different applications. Inorganic Glass Fibre, Polyester, Celulose, Stainless Fibre Material and Stainless Steel Wire Mesh are used for hydraulic applications.

- Inorganic Glass Fibre.- Material based on synthetic fibres with acrylic resin binding that offers a large dirt-hold capacity and an excellent separation efficiency (3-25µm) due its labyrinth structure.

- Polyester Fibre.- 100% Polyester Fibres with thermal bonding that offer a high pressure differential resistance, a large dirt-hold capacity and an excellent separation efficiency (3-25µm) with a low flow resistance, good chemical resistance and tear-proof structure.

- Cellulose Fibre.- Filter material made of Cellulose Fibres with special impregnation, it is a variant with the lowest price and a good dirt-hold capacity and a separation efficiency from 10µm to 50µm. Not suitable for water based fluids.

- Stainlees Fibre.- Sintered Stainless Fibres with three-dimensional labyrinth structure that offer a large dirt-hold capacity and an excellent separation efficiency (3-25µm) with a low flow resistance, good chemical and thermal resistance.

- Stainlees Mesh.- Wire Mesh (square weave or Duch weave) fabric made of material 1.4301 or 1.4305 for surface that offers a low flow resistance due to large-pored screening surface and a separation efficiency from 10µm to 1000µm, excellent chemical and thermal resistance.

- O-ring seals with configurable materials (NBR, EPDM, Teflón) depending on applications, in addition to resistant end caps and rugged metal inner core as part of the filter housing, complete this competitive product, reducing maintenance and remplacement costs.

Description

High performance Nortek filters incorporate state-of-the-art design technology, including a pleat support system and composite element structure for unsurpassed strength, performance and service life.

Applications

The Nortek filters of series 420XXXX are suitable for hydraulic systems, lubrication mechanisms and fluid control. This filters are installed in the Return-Line, on top of or within the oil tank, filtering the hydraulic oil before it flows back into the reservoir. This ensures that contamination arising in the components does not get into the tank. This filters work under conditions of low pressure and temperature, its action allows to preserve the useful life of both the components of the equipment and of hydraulic fluid.

Design and operating principle

Both the design and the composition of the elements, are thought-out improving the circulation of the oil through the filter, minimizing the loss of charge and retaining contaminants as it passes through the filtering elements according to the degree of filtration you want to obtain (Beta Ratio « β »: The number of incoming particles in the filter, divided by the number of particles leaving the filter).

The effectiveness of the filter element in the control of contaminants depends on its design and its sensitivity to any unstable operating condition, which may stress and damage the filter element.

Installation

In the installation of these filter elements, the type of process must be taken into account, in order to adapt the element according to the needs and the most efficient way possible.

Spécifications

| Specifications | |

| Pressure drop | (see Flow characteristics curves) |

| Collapse Pressure | 10…210 bar (145…362 psi), according to standard ISO 2941 ( ANSI B93.25 ) |

| Fluid Compatibility | Petroleum oils, coolants, water-oil emulsions

According to standard ISO 2943 ( ANSI B93.23 ) |

| End load test | According to standard ISO 3723 |

| Flow Fatigue | According to standard ISO 3724 ( ANSI B93.24 ) |

| Temperature Range | 0 – 107ºC ( 0 – 225ºF ) para la mayoría de los fluidos hidráulicos |

| 0 – 65ºC ( 0 – 150ºF ) para refrigerantes | |

| 0 – 93ºC ( 0 – 200ºF ) para derivados del petróleo | |

| Diameter of nozzle | 60mm ÷ 143mm ( 2,36” ÷ 5,63” ) |

| Performance test Multi-pass | According to standard ISO 16889 |

| Bubble-point test method | According to standard ISO 2942 |

| Flow characteristics | According to standard ISO 3968 |

| O-rings | NBR – EPDM – Teflón |

| Model cartridge | 421 A B C D |

| According to size – A (see chart in Dimensional drawing) | |

| 008 | |

| 014 | |

| 030 | |

| 035 | |

| 045 | |

| 070 | |

| 090 | |

| 125 | |

| 130 | |

| 160 | |

| 250 | |

| 300 | |

| According to filtration – B Micron | |

| 3 | 1 |

| 5 | 2 |

| 10 | 3 |

| 20 | 4 |

| According to material – C Type | |

| Glass fiber 30 bar | 1 |

| Glass fiber 210 bar | 2 |

| According to ring material – D Material | |

| NBR | 1 |

| EPDM | 2 |

| TEFLON | 3 |

Informations sur la commande

| 421014311 | Size cartridge 014 Filtration 10 micron Made of fiber glass 30 bar O-ring NBR |

D'autres produits

Nous vous répondrons dans les 24 heures

Avez-vous des questions ? Êtes-vous prêt à acheter ? Votre assistant Nortek est prêt à vous aider

Histoires de réussite

Nous sommes votre partenaire fiable pour que tout s’enchaîne et que rien ne s’arrête.

Confiez-nous la gestion des fluides de toutes vos machines pour qu’elles fonctionnent toujours à 100 %, augmentent leurs performances et prolongent leur durée de vie. Il est temps de cesser de vous préoccuper des performances de vos machines.

Découvrez comment nos solutions ont donné d’excellents résultats